Monitor and stabilise your processes and save raw materials

Real-time monitoring of quantity of raw materials such as super absorbent polymers, fibres, nonwovens, and other materials, in real-time.

Solution Features

Save raw materials such as super absorbent polymers, fibres, nonwovens, and other by monitoring process stability.

An easy to use and secure cloud-based software suite, to support operators, quality managers, product managers, marketing professionals and process engineers in their day-to-day challenges.

Multiperiod Production Statistics and Yield KPIs

Detection of Dosage Variability to ensure process stability

Assessing Losses and potential gains in real-time

Studying your raw materials usage and cost across products, and over various periods of time

Detecting and Alert Underdosage or Overdosage periods in real-time

Quality Ensurance and Higher Yield

Excellent Products shipped to customers

Beyond avoiding overdosing, you will be able to avoid underdosing too; therefore, best quality is being produced. We have measured that your productivity rate can potentially increase by around 100 thousand diapers per year, per production line, by avoiding diaper rejection due to underdosage. Take control of your product specifications by ensuring that good products are not wasted and are shipped to customers.

SUSTAINABILITY

Less Plastic – Less CO2 – Smaller landfills

Stabilising your production dosing can allow you to reduce dosage without affecting production quality. Reducing the weight by 1 gram per diaper while mastering the standard deviation would lead to more than 100 Tonnes of less plastic waste per year. This is equivalent to a reduction of more than 500 Tonnes of CO2 emissions per year for a single production line.

OPERATIONAL EFFICIENCY

Support operators with real-time KPIs

10 minutes of gained productivity per day translates to more than 5000€ of financial gains! It is very hectic on the production line and getting simplified key production metrics will facilitate operations, increase production output, and increase the quality of life at work.

PRODUCE MORE FROM LESS

Improve Supply Chain Planning

By mastering the dosage of SAP/SAM, you will be able to produce more products from the same amount of procured SAP/SAM. SAPgram will help you gain more visibility on your SAP/SAM usage from the shift to the year!

SAPgram’s modules offer statistical analysis and KPIs related to raw material usage, production volume, yield and cost.

USER EXPERIENCE

Making the lives of operators simpler

Easy to use Software designed for comfort, accessibility, and good communication. SAPgram is a user-centred software, designed for an excellent user experience.

Install >

Analyse >

Save

Install >

Analyse >

Save

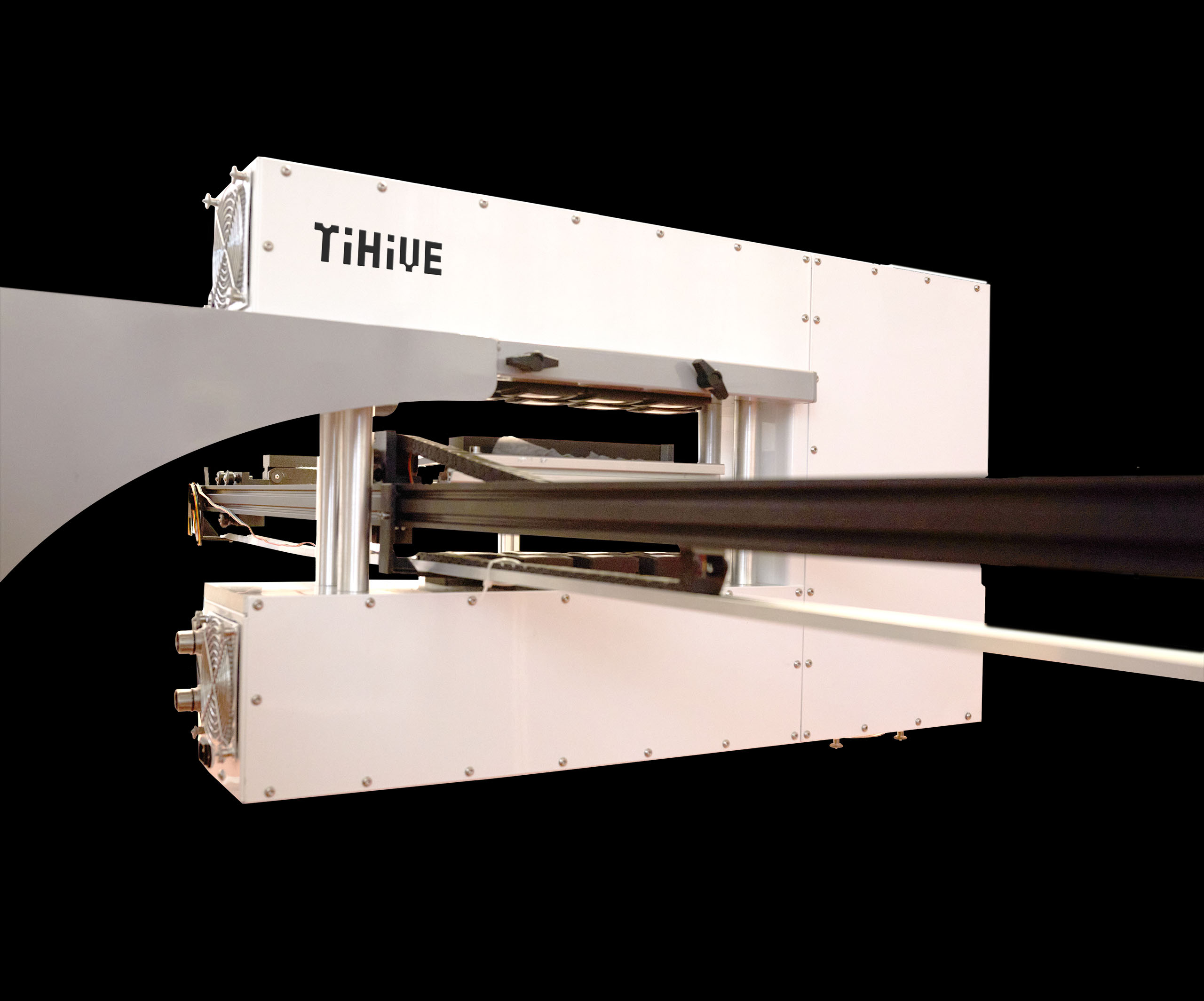

How it works

Our engineering team has simplified the installation and setup of our solution for a seamless experience. Our team will coordinate with your team to install our monitoring hardware within an hour followed by a few simple calibration steps. Our support team will accompany your team to be operational from day one on analysing the data generated to accelerate your return on investment.

SUBSCRIPTION MODEL

Master the return of investment

We have designed our solution to bring immediate returns on your investment. This is why we have innovated in our business model too. Via a simple and effective subscription model you will be able to deploy our different software products across your production lines without the burden of huge CAPEX costs.

Learn more and book a demo with our team.