Destructive and Non Destructive Testing: A Practical Guide for Manufacturers

Modern Manufacturers Rethink Inspection Methods

Manufacturing players are under constant pressure: tighter specs, faster lines, and growing expectations from regulators, retailers, and end users. Testing strategies are at the heart of this challenge.

For decades, destructive and non destructive testing have been the standard ways to validate material properties and ensure product reliability. Today, however, new non-destructive inspection technologies, including terahertz-based imaging, are changing how we think about quality control in manufacturing.

This article explains the differences between destructive and non-destructive testing, when to use each, and how advanced inline inspection can improve both factory performance and people’s quality of life.

What Is Destructive Testing?

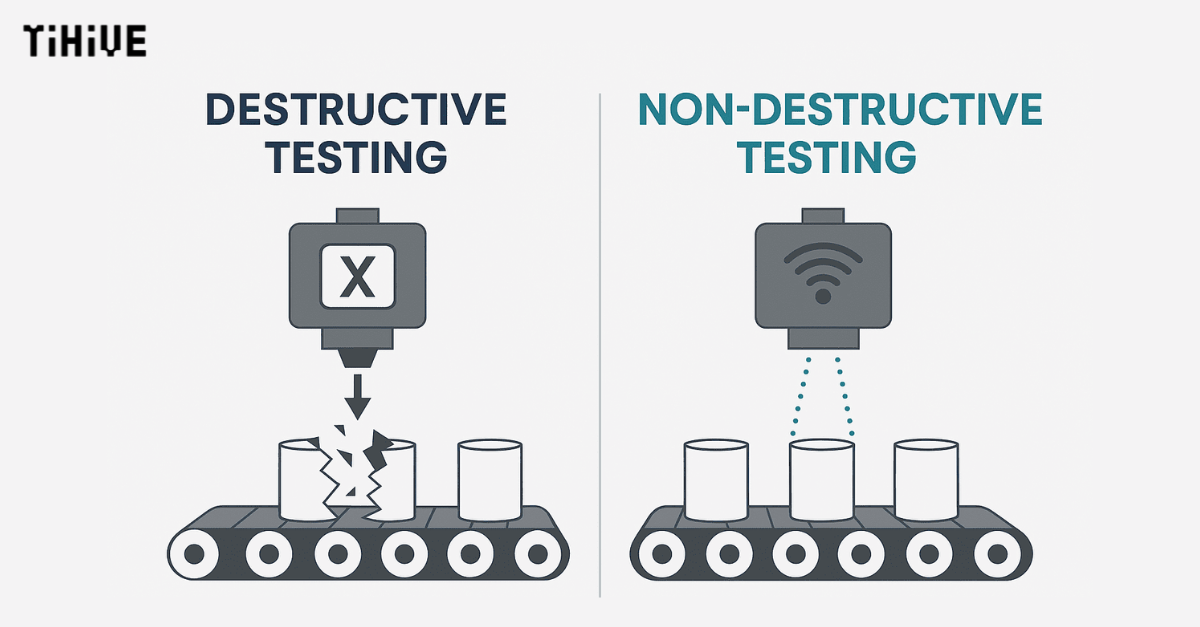

Destructive testing (DT) is a testing approach where you deliberately push a component, sample, or product to failure to understand its true performance limits.

In practice, this includes methods such as:

Tensile and compression tests: measure strength, elasticity, yield and breaking point

Fatigue testing: repeated loading cycles until failure

Impact and fracture toughness tests: understand behavior under shock or crack propagation

Creep tests: evaluate long-term deformation under constant load and temperature

DT is typically used:

- During R&D and product design to validate simulations and safety factors

- When qualifying new materials or suppliers

- For regulatory or certification purposes where full failure data is needed

Advantages of Destructive Testing

- Very detailed insight into material behavior and failure modes

- Essential for defining design limits, safety margins and standards compliance

- Often required for type approval in industries like aerospace, automotive, and construction

Limitations for Modern Production

For operations leaders and plant managers, destructive testing has clear drawbacks:

- Samples are destroyed: no possibility to sell them

- Low sampling rates: only a tiny fraction of production is tested

- Delayed feedback: testing often happens offline, sometimes in external labs

- Risk of undetected defects in the field if only a few samples are checked

In other words: destructive testing is powerful but not scalable when you want near-zero defects at high speed.

What Is Non-Destructive Testing (NDT) and Non-Destructive Inspection?

Non-Destructive Testing (NDT), also called non-destructive inspection (NDI) or non-destructive evaluation (NDE), refers to techniques that assess a material, component, or structure without damaging it.

source:Unitek Technical Systems+1

Common NDT methods include:

- Visual Testing (VT): manual or automated cameras, often with AI-based defect recognition

- Ultrasonic Testing (UT): high-frequency sound waves to detect internal flaws

- Radiographic Testing (RT): X-ray or gamma ray imaging of internal structures

- Magnetic Particle Testing (MT): for ferromagnetic materials and surface-breaking defects

- Dye Penetrant Testing (PT): reveals surface cracks through capillary action

- Eddy Current Testing (ECT): electromagnetic method for surface and near-surface flaws

These methods are widely used across oil & gas, aerospace, automotive, rail, energy, and manufacturing to keep assets safe and reduce unplanned downtime.

Benefits of Non-Destructive Testing

From an operations perspective, NDT offers clear advantages:

- Components remain intact and can go back into service or be shipped to customers

- Testing can be done during manufacturing or in service, not only in the lab

- Support for predictive maintenance and condition-based monitoring

- Better balance between productivity, quality, and safety

In advanced factories, non-destructive inspection is being integrated directly into the line to support zero defect manufacturing and zero waste strategies.

Before diving into the limits of NDT, let’s see what’s the main difference between the two methods.

Destructive vs Non Destructive Testing: How to Choose in Manufacturing

For quality managers, the key question is not “which is better?”, but “which method fits this phase of the product life cycle and this risk profile?”

- Stage of product lifecycle

- R&D / validation: more destructive tests

- Routine production: more non-destructive inspection

- Criticality of component

- Safety-critical, high-liability parts: combine both DT and NDT

- Cost of each part

- High-value items: NDT preferred to avoid scrap

- Required sampling rate

- 100% inspection or high coverage: NDT / inline systems

- Regulatory & customer requirements

- Many standards require specific mixes of DT and NDT

In practice, most manufacturers end up with a hybrid strategy: Use destructive testing to validate design and material behavior, then rely on non-destructive testing and inline inspection to keep everyday production under control.

The Limits of Traditional NDT in High-Speed Manufacturing

Classical NDT techniques are powerful, but many of them were designed for offline inspection, manual workflows, and low-volume environments.

In high-speed production (for example, hygiene products, medical disposables, or packaging), teams face several challenges:

- Sampling-based inspection

- Only a fraction of units is ever inspected

- Risk of passing systemic defects to the market

- Manual or semi-automated processes

- Operator-dependent, subject to variation

- Safety and integration constraints

- Radiography requires shielding and strict procedures

- Limited process analytics

- Results are often stored as reports, not real-time data feeding the line

To reach zero defect / zero waste manufacturing objectives, industry leaders are now turning to smart, inline non-destructive inspection technologies integrated with automation, MES, and AI analytics.

Terahertz Imaging: A New Generation of Non-Destructive Inspection

Among emerging technologies, terahertz (THz) imaging is gaining strong traction for inline, high-speed non-destructive inspection.

What is terahertz?

Terahertz waves sit between microwaves and infrared on the electromagnetic spectrum. They are non-ionizing and safe, yet highly sensitive to subtle changes in material properties such as:

- Thickness and layer structure

- Density and porosity

- Moisture / humidity content

- Hidden defects within non-conductive or multilayer materials

Because of these properties, terahertz imaging is particularly powerful for soft, multilayer, and absorbent structures such as those found in baby diapers, adult incontinence products, femcare, and many medical or hygiene products.

Why THz Matters for Quality Control in Manufacturing

For production and quality leaders, terahertz-based non-destructive inspection offers several key advantages:

- Inline, 100% inspection at or near full production speed

- Ability to “see inside” the product core without cutting it open

- Real-time data streams that feed closed-loop control and process capability (Cp, Cpk) analysis

- Safer alternative to ionizing radiation for many applications

- Direct insight into SAP distribution, material basis weight, density and humidity in hygiene products

Combined with AI-driven analytics, terahertz inspection can help detect process drift early, reduce scrap, and stabilize Overall Equipment Effectiveness (OEE) over time.

A Smarter Approach to Testing

Destructive and non destructive testing are not in competition, they are complementary.

Manufacturers now use:

- Destructive testing for deep validation and R&D

- Non-destructive inspection, ideally inline, for real-time process control

With TiHive’s solutions that combine terahertz imaging and AI-driven analytics, our partners and clients can now inspect every product, detect process drift instantly, and move toward true zero-defect manufacturing.

In other words, quality becomes continuous, decisions are driven by real-time insights & data, and testing becomes a strategic asset.

Planning your next project, exploring smarter quality control or would simply like to learn more about how we can help?

Schedule a call with our Experts to know exactly how non-destructive terahertz and AI inspection solutions can add value to your processes and help you achieve your manufacturing goals.